Almost Afters: Gail's New Fireplace

Last Friday I attended my last official site meeting for

Gail's Kitchen and Family Room renovation. I started working on this project on Dec.11th, 2009 so its been a looong process seeing this new space evolve from paper to reality week after week. This last meeting represented what I call substantial completion, meaning the construction is considered complete, and the homeowner moves back into her new space!!! The crew packs up all their things and they move-on to another job site, returning as needed to finish off any outstanding small items.

When I was at the house early that morning, the guys were doing some final paint touch-ups, I didn't have the opportunity to take any 'after' shots because they were just about to start the big clean-up but I'll be back for a follow-up visit very soon. One of my FAVORITE things in the space was the new family room fireplace and last week was the very first time I had seen it. The fireplace itself is a new clean face model gas unit by Napoleon. Since my previous visit the new surround and mantle had been installed so it was a bit of a 'reveal' moment for me when I walked in, and when I saw it there, I just stopped in my tracks and gasped! : ) The design concept for the fireplace had changed several times over the past couple of months....

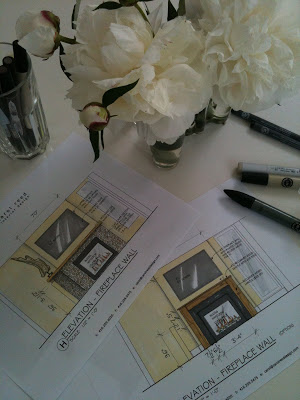

Here are a couple of initial concepts,,,in each I had envisioned antique or reclaimed wood being used for the mantle. It was an awkward space, to the immediate right was a window to the immediate left is a half wall with stairs to the basement and the fireplace wall is also the only wall in the room for the tv.

A short time later we discovered a stash of antique wood boards in the homeowners garage (located in an income property they own across the street). Of course I went crazy over them and asked the contractor to make us a rolling door from the boards and.......if there was enough material I also wanted to use it for the fireplace mantle.

Then about a month later,,,,,the coppersmith visited the house to do a site measure for the new custom copper hood canopy I had designed. He brought a few samples for me to review and as soon as I saw them I asked if he could also make the fireplace surround out of the same copper. No problem he said (Oh I love to hear that!!!) so I sent him a sketch with dimensions....

Excuse the ugly 3D image, (this is why I prefer hand renderrings) but I used this 3D sketch to illustrate how I wanted the copper surround and the wood mantle to be built. A seperate sketch had all the dimensions on it. I emailed this to the copper smith and my contractor who was making the mantle. Unfortunately my contractor called me to say there wouldn't be enough of the antique wood left over from the door so what was plan 'b' ? I asked him if he could find some rough hewn, gnarly wood that was about 2" x 6",,,,,, and that was the last I heard from him.

A few days later I showed up for my final site meeting and this was what they had built. I LOVE it!!!

The homeowner is over the moon about it, and seriously I wish this fireplace was in my own home. Its rustic and contemporary and I have to say I've never seen anything else like it, my contractor hit it outta the park with this one. The wood he used was rough-hewn douglas fir, the knots are absolutely gorgeous and have the same character as the loft grade natural oak floor. When I took this photo it wasn't quite 100% finished yet, the mantle was about to receive one more light sanding and a coat of oil. Then the copper surround gets a once over with steel wool to remove some of the black coating and bring out the copper, the steel wool also gives it a low lustre sheen.

I hope you enjoyed this little glimpse of what the 'almost' finished space looks like, I have to say its a dramatic transformation from what was once there and I can't wait to post all the after photos.

Note: When building a surround and or mantle for any gas fireplace, its critical to refer to the mfg's installation specifications where you'll find all the minimum clearances that must be maintained. There are strict clearances that must to be adhered to with regards to the use of combustible and non-combustible materials when cladding the surround and there are various clearance requirements with regards to mantle projections. Always follow the mfg's specs for your exact model.

All Photos: Carol Reed